Fresh Produce

Pooling

Right Crate, Right Place, Right Time. Simple.

Our reusable produce containers (RPCs) get products safely from farm to warehouse to retailers. And, we make it simple, flexible, and frictionless.

We believe no resource should end up in landfill. When an RPC reaches end-of-life, we recycle it. Because on a finite planet, we’re building an infinite loop.

Fresh Produce Pooling

Efficient. Circular.

Retail-Ready

Viscount’s closed-loop pooling system powers major supermarkets across Australia; streamlining logistics while slashing waste. Our reusable plastic crates (RPCs) arrive washed, sanitised, and ready to load. Once produce hits the shelves, the crates return to us for cleaning and redistribution. No hassle, no waste, just smart, sustainable movement.

Our Pooling Process

RPC’s sorted, washed

and inspected

Collapsed crates are collected from Retailer’s DC, or markets streamlining returns.

Collapsed crates collected

by produce growers

RPCs are sorted, washed, and thoroughly inspected to meet strict hygiene and quality standards. This process ensures every crate is safe, clean, and ready for reuse in the supply chain.

RPCs filled

at farm

RPCs are filled with fresh produce right at the farm, locking in quality from the start.

This ensures every crate delivers clean, safe, and ready-to-sell goods all the way to retailers.

Full crates delivered

to market

Full crates are delivered straight to the retailer’s distribution center, ensuring fresh produce arrives safely and efficiently. This seamless transfer keeps supply chains moving and shelves stocked with quality goods.

Crates delivered to retail store

Crates arrive at the retailer as point-of-sale solutions, ready to showcase fresh produce straight from the farm.

Empty crates delivered

to retailer’s DC or markets

Empty crates delivered to retailer’s DC or markets.

RPC’s sorted, washed

and inspected

Collapsed crates collected

by produce growers

RPCs filled

at farm

Full crates delivered

to market

Crates delivered to retail store

Empty crates delivered

to retailer’s DC or markets

How do we do it?

Track & Trace Technology for Supply Chain Transparency

Best in Class

Hygiene and Food Safety Standards

Online

Grower Portal

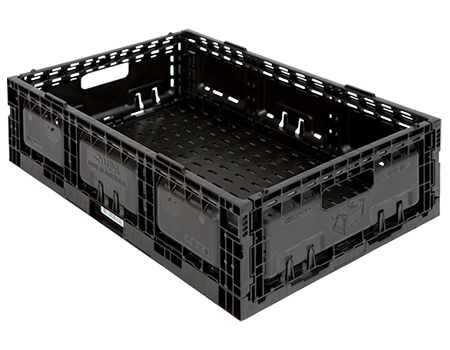

Our Range

Viscount’s retail-ready, collapsible Intellicrate® RPCs streamline every step of the supply chain; cutting waste, saving space, and delivering fresh produce with maximum efficiency and minimal environmental impact.

View Intellicrate® Supplier Guide

Best in Class

Hygiene and Food

Safety Standards

To ensure the highest global hygiene standards, Viscount leverages world-class technology and lot tracking, and engages independent bodies for ongoing monitoring and condition reporting. This rigorous approach mitigates contamination risks and reinforces our commitment to safety, transparency, and operational excellence.

Leveraging Technology to

Make Your Supply Chain

Fast, Transparent and Traceable

Viscount is scaling the future of supply chain visibility with Track & Trace technology. Every pooling product is built ready for activation — giving customers real-time insight into asset movement across warehouses, wash centres, and distribution networks.

Seamlessly integrated into your operations, our RFID systems unlock smarter logistics, reduce loss, and power data-driven decisions. It’s traceability that delivers clarity, control, and confidence.

Our Impact in Numbers

Online Grower Portal

Built in close collaboration with growers and supply chain partners, Viscount’s online portal puts real-time asset visibility at your fingertips. It’s designed to reduce penalties, cut waste, and give growers a faster, smarter way to manage their inventory from paddock to packhouse.